Published by ELE Times

There are a number of challenges for designers of wireless charging products. In addition to issues associated with the magnetics, they have to deal with efficiency, mechanical packaging and electromagnetic interference (EMI). However, with optimized components and if certain basic criteria like the alignment of charger and device, size of coils and distance between coils relative to the size of the coil are met, then a good coupling factor can be achieved, and power can be transferred with high efficiency. In addition, metallic foreign objects (such as coins and keys) may interfere with the charging and have to be detected (FOD, Foreign Object Detection).

The technology is moving from transmitters that charge single devices to transmitters that can charge several devices simultaneously, using either multi-coil inductive or resonant charging.

Key to the success of the overall wireless charging ecosystem will be the adoption of the technology into applications beyond smartphones, such as wearables, medical instruments, robots, drones and point of sale terminals. Infineon’s array of wireless charging solutions range from low-power support for charging using very small coils and multi-device charging, to a flexible high-power offering that is backward compatible for lower-power products such as smartphones. These types of charging experiences are not supported by existing smartphone charging solutions.

Inductive and resonant

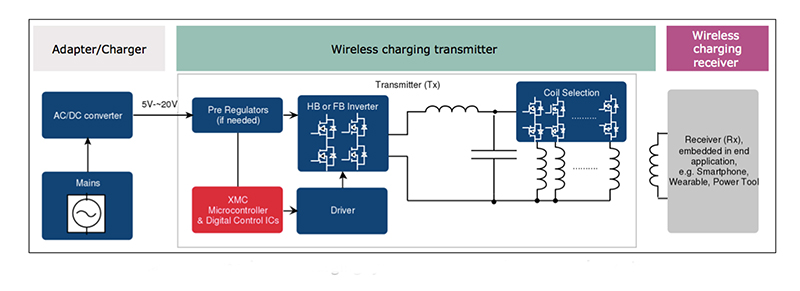

Wireless charging solutions typically have three key elements; the adapter/charger, the transmitter and the receiver. The adapter connects to the mains supply and powers the transmitter, usually with a regulated DC voltage in the range 5- 20 V. The transmitter contains a MOSFET-based inverter to convert the DC power into an AC waveform and create the alternating magnetic field. This is often a half-bridge or full-bridge topology. In order to provide the flexibility and functionality required, the inverter is controlled by a microcontroller and associated MOSFET driver components.There are differences in the types of magnetic induction technology – inductive and resonant.

Looking at inductive first, there is the standard single coil inductive charge transmitter. This requires positioning the device being charged directly over the coil on the charger and is limited to charging a single device. With good design and high-quality power conversion electronics the efficiency of charging in the 100-300 kHz band can match wired charging. Multi-coil inductive chargers provide more horizontal freedom to play with in terms of device positioning.

With resonant chargers, the largest difference is that the 6.78 MHz frequency of magnetic resonance charging can achieve a much larger vertical range of 50mm or more. Multiple devices can be charged from a single larger coil and the broader field of operation means the charger has a larger “sweet spot” for efficiency. So, while the inductive design can achieve high efficiency with precise positioning, the resonant approach allows greater freedom of positioning.

Although a very closely coupled inductive solution can deliver more power in a very precisely defined and controlled scenario, as soon as the placement alters then the resonant approach gives a far more efficient energy transfer with spatial freedom.The resonant approach also allows multiple device types to be charged wirelessly. The technology is not affected by the presence of metallic objects in the charging area.

The multi-coil brings a number of benefits. The positioning of the device is much less precise and smart systems can detect which coil is closest to the device being charged and direct the power accordingly.

Operating at 6.78 MHz, the resonant charging approach relies on resonance between the transmitter and receiver to transfer energy far more efficiently. The resonant approach is able to charge multiple devices from a single coil and allows for a greater distance (up to 50 mm) between the transmitter and receiver.

Improved EMI and system efficiency

Existing class D full-bridge architecture (using a series resonant LC) drives the coil with a square wave. This square wave injects multiple higher-order harmonics with significant power and very difficult to filter. The required filters to manage this EMI create losses and can be expensive. Strong higher-order harmonics reduces overall system efficiency.

In EMI restrictive environments, such as automotive, a new Infineon architecture drives the coil with a pseudo-sine wave voltage. This driving waveform contains fewer and lower amplitude higher-order harmonics compared to class D. The simpler filters required to manage this EMI reduce efficiency losses and reduce overall transmitter cost.

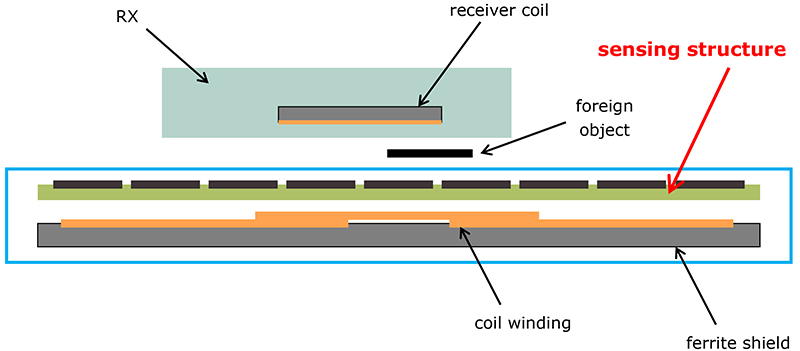

The standard FOD method relies on the large primary coil winding for detecting foreign objects, which reduces sensitivity and signal to noise ratio. Smaller objects are difficult to detect, due to the small impact on the magnetic field of the much larger primary coil. Existing transmitter solutions measure the parameters needed for the power delta calculation (voltage and current) at the DC side of the coil driver. This distorts the measurement when compared with the actual values at the coil, causing an inaccurate transmitter loss calculation.

An improved FOD method uses smaller sensing elements to detect small foreign objects, which greatly increases sensitivity and signal to noise ratio. This approach improves accuracy of the coil quality factor measurement to ensure even the smallest foreign objects are detected at the start of charging, even outside of the primary coil area.

Flexible software-based architecture

Rather than rely on an application specific IC for protocol and power delivery, the strength of the Infineon wireless charging solution lies in its modular software-based architecture. Wireless charging is continually evolving, as standards mature, and new products and applications are introduced to the market. The high software content of the solution allows a common hardware architecture to be used across several reference designs, with each reference design flexible enough to support several types of applications. In addition, future changes to the wireless charging standards can be supported by a software upgrade, which creates a future-proof product design that can span multiple generations.

The software is responsible for directing all major wireless charging functions in the system. A fully digital demodulation scheme provides greater sensitivity for decoding communication in times of weak coil coupling due to misalignment, and also ensures the highest level of interoperability with legacy receivers. Next-generation parameter measurement techniques ensure the highest accuracy for optimal power delivery and FOD. Precise control of frequency, duty cycle and voltage provide the correct level of rectified power at the receiver, and two-way communication on some systems enables smart charging with two-way authentication. Underneath the higher-level functions, a real-time engine keeps track of every aspect of transmitter operation from input supply, to efficiency, to thermal performance and makes adjustments as required. Finally, a self-calibration step during initial transmitter power-up provides a predictable baseline performance ensuring each product meets the requirements of the application.

AURIX and XMCsupport wireless charging

Efficient and easy-to-use wireless charging for smartphones, wearables, medical and industrial devices is supported by the AURIX and XMC microcontroller families. Flexible chip sets for high performance including software IP for smart and safe wireless charging applications are available. Working with a systems solution partner, Infineon provides reference designs for both inductive and resonant wireless charging solutions: for on-the-go charging, whether in the car, at home or in public places.

The controller works seamlessly with power devices from Infineon to provide a complete charging solution. Optimized voltage regulators, drivers and power MOSFETs enable high efficiency power conversion, while network ICs serve for reliable communication according to highest automotive standards. The complete solutions support future changes with a software update. An enhanced power stage architecture improves EMI performance 10-15 dB over existing solutions on the market. A newly developed supplemental FOD system provides enhanced detection accuracy to meet critical customer safety requirements.

AURIX microcontrollers help the next-generation in-cabin wireless charging systems meet strict automotive safety, security, environmental and regulatory requirements. On the other hand, XMC microcontrollers provide a powerful and cost-effective platform. The scalable architecture can support everything from a fast charge Smartphone, to a 20 W robot, up to a 60 W drone and beyond. Paired with related power products, like MOSFETs and driver ICs, this system can provide full power wireless charging without complicated thermal management, often achieving charging rates equivalent to wired charging.

Reference designs

Infineon provides complete reference designs that support many of the current and next-generation wireless charging applications. These reference designs include the hardware design, bill of materials, example PCB layout and all the documentation required to integrate wireless charging into the customer’s product.

The XMC based 2.5 W low-power solution is the industry’s lowest cost resonant wireless charger. By using a higher frequency (6.78 MHz), very small coils can be employed in a variety of form factors, with no regard to nearby metallic objects. These benefits make the technology ideal for charging wearables, headphones, smart clothing and other connected IoT applications.

An inductive Smartphone/handheld solution provides 15 W charging and existing standards, including fast charge smart phones with high efficiency charging without special thermal management. It achieves charging rates equivalent to wired charging and supports custom charging profiles and industry standards on the same hardware.

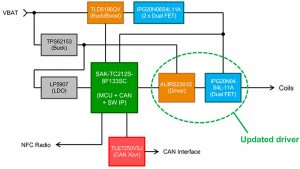

An inductive automotive in-cabin solution supports 15W charging and all existing standards, including fast charge smart phones. The solution allows the charging of two devices by using a single controller. This single AURIX controller supports wireless charging, system application, CAN and external NFC interface. Built in security functionality meets latest automotive requirements.

A 60 W inductive wireless charging solution for various devices provides industry’s highest power levels on the smallest coils. It offers high efficiency charging up to 60 W without exotic thermal management. The solution is backward-compatible with Smartphone charging standards (5 W or 15 W) and fast charge devices. Typical applications are power tools, laptops, robots, small appliances, drones, handheld terminals, medical instruments, industrial automation.

Dedicated microcontrollers for wireless charging

The AURIX wireless power controllers like the SAK-TC212S-8F133SC helps the next-generation in-cabin wireless charging systems meet strict automotive safety, security, environmental and regulatory requirements, while still enabling industry-leading charging performance and efficiency. This controller works seamlessly with Infineon’s power and interface devices to provide a complete charging solution for smart phones and other connected devices

Infineon’s wireless power controller XMC751SC-Q040 and the other members of this series based on the ARM Cortex-M0 core works seamlessly with Infineon’s power devices in a scalable and cost-effective architecture to provide a complete charging solution for everything from a fast charge Smartphone, to a 20 W robot, to a 60 W drone and beyond.