Nobody can argue that Wireless Charging is an incredibly convenient way to keep our favorite handheld devices charged up, and to provide some remedy for battery anxiety. Wireless charging is (almost) everywhere nowadays — in our phones, in our cars, in our airports, in our restaurants and coffee shops, and soon to be in places we haven’t even thought of yet. But is it safe? We have seen internet articles about wireless charging shortening the life of your smartphone’s battery, or other ways wireless charging can harm your device. But unfortunately, those articles are not written by people who understand wireless charging, and are false and misleading. (Spoiler: There is no difference in charging your phone from a wire or from wireless — it’s just another way of getting energy.)

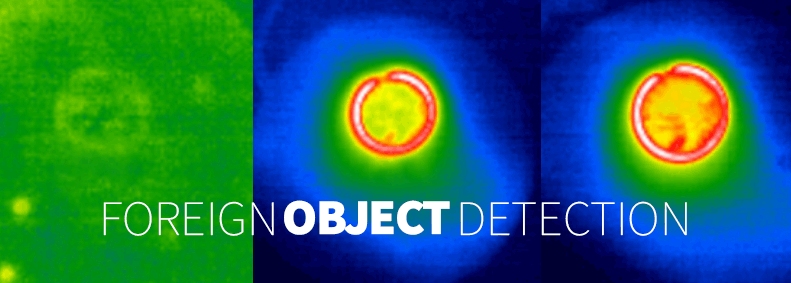

Back to our question: Is wireless charging safe? The answer, of course, is a resounding “yes”, provided it is done correctly. One of the biggest safety topics to understand in a modern-day wireless charger is how to prevent the wireless charger from heating metal objects to unsafe levels. Because the frequency used by the wireless charger is very effective at heating metal objects, it is up to us as system designers to ensure that any stray metal objects, such as wayward coins, that present themselves in the middle of a charging session are not a cause for alarm (as in “fire alarm”). In order to protect ourselves from these “foreign” metal objects, we try to detect this safety threat with something called “Foreign Object Detection”, or FOD.

Historically, ever since the introduction of Foreign Object Detection (FOD) methods in the Wireless Power Consortium Qi (pronounced “chee”) standard, the general public has had a misunderstanding of what FOD really means.

If a random person is asked what FOD must do, in most cases the answer would be that if a coin is placed on the transmitter surface, the transmitter should indicate the presence of a foreign object. This is basically the functionality of a metal detector.

In practice most receivers like phones and battery packs have metal elements around the receiving coil. User experience can be negatively affected if these metal elements are wrongly classified as foreign objects. According to the Qi specification, a foreign object is detected only after a Qi receiver is placed on the transmitter surface, information is exchanged between the two devices and a decision is made about the foreign object presence based on the estimation of how much power would actually be dissipated into the foreign object during power transfer. It is perfectly acceptable to have an object on the transmitter surface during power transfer if it does not heat above certain thresholds.

OBJECT PLACEMENT ON THE TRANSMITTER SURFACE

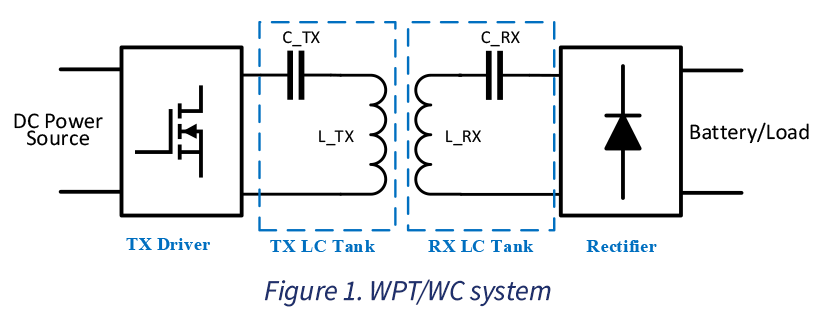

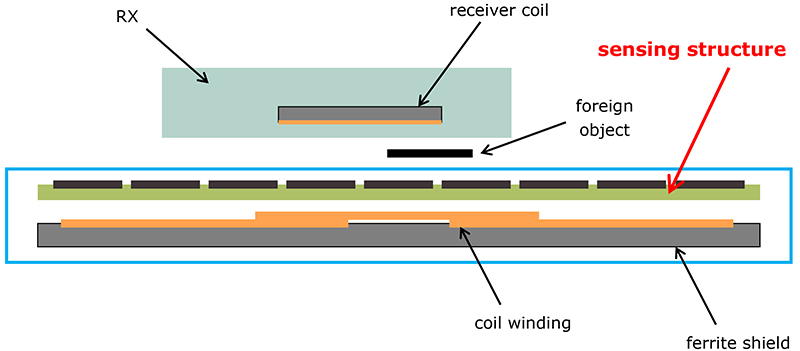

The most popular method to detect the presence of an object on the transmitter surface is the Direct Q Measurement. It monitors for changes to the quality factor (Q factor) of the transmitter coil or for changes in its inductance or resistance. Other methods that detect the presence of objects on the transmitter coil can be based on change in capacitance, light reflection or transmission, changes in weight/pressure, resonance at 1MHz, metal detectors using auxiliary coils, etc.

The Qi specification has an informative section reserved for these mechanisms. The resonance shift method is already described and is related to the change in quality factor. The fact that a resistance change is also induced by most (but not all) receivers can be used to improve the detection of the object but it is not enough to determine if the presumed foreign object would actually absorb enough energy during power transfer to cause a significant increase in its temperature.

CONFUSION BETWEEN THE DIRECT Q MEASUREMENT AND THE EXISTING PRE-POWER FOD METHOD

These values are measured when a receiver is placed on a MP-A1 transmitter coil and they are reported by the receiver during the negotiation phase.

The transmitter may not use a MP-A1 coil and in that case its measurements of Q and resonant frequency must be converted from the actual transmitter coil to how they would look like on the MP-A1 coil before a decision can be made regarding the mismatch between the measured values and the reported values from the receiver.

The Qi specification has a high-level description of the pre-power FOD methods but the mechanism used to calculate the Q factor seen by a MP-A1 coil is not provided.

The direct measurement of the transmitter coil quality factor without a receiver present can at most inform the transmitter of the existence of metallic objects on the charging surface, and the transmitter can use this data to inform the user to clear these objects before placing the receiver on the surface. This method can also be used after a confirmed FOD event and subsequent removal of power. In that case, the transmitter uses this method to ensure the user has removed all objects from the charging surface before allowing the receiver to be placed to restart charging.

This method alone cannot determine if the metallic object will consume sufficient power to heat the object, but it can be used in combination with other power loss methods to educate the user to always remove all metal objects from the transmitter surface before/during/after charging.

Confusing? The key is in the name of the action: Foreign Object Detection. It’s one thing to detect a metal object, but it’s a whole different ballgame to determine if that object will lead to an unsafe situation if we charge a phone while that object is present. As a charger, what you want to do is charge a user’s battery — that is, after all, the reason you exist. Therefore a charger must have a robust and deterministic plan for deciding which objects are clearly unsafe, and which objects can still be present during a charging cycle without cause for alarm. If I am too conservative, then nobody gets to charge. But if I am too lenient, then somebody gets burned (maybe literally). Striking the right, and safe, balance is the art of good transmitter design.

“It is perfectly acceptable to have an object on the transmitter surface during power transfer if it does not heat above certain thresholds.” – Emanuel Stingu, Chief Technology Officer at Spark Connected.

About Spark Connected

Spark Connected | powering the world, wirelessly

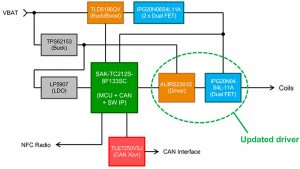

Spark connected is an industry leader specializing in multiple advanced and safe wireless power technologies that benefits a wide variety of applications in the Automotive, Industrial, Infrastructure, Medical, Telecom and Security, Robotics, Factory Automation, IOT, Smart Home, and Consumer markets.

Spark is transforming wireless power delivery and intelligent battery charging with innovative platforms, disruptive technology and breakthrough products enabling an enhanced user experience for all. The company specializes in Product Development and Engineering Solutions with a team of passionate innovators with decades of combined deep domain expertise.

Spark Connected is a Full Member of the Wireless Power Consortium.

Please forward inquiries to:

Marina Wolf/Ruwanga Dassanayake

(972) 855-8026

sales(at)sparkconnected.com